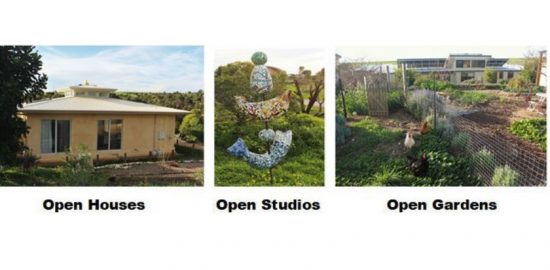

Unley Spring Fling event

The right to repair

Repair Cafés in South Australia

We can be more sustainable

A new sustainable future

Living Smart Mount Barker

Sustainable Garden Awards

Unley Repair Cafe

Website & media – we need your help!

Strategic plan for Sustainable Communities SA